A gemstone oiling and crack filling machine is a specialized tool used in the jewelry and gemstone industry to enhance the appearance and durability of precious stones. This comprehensive guide explores the principles, applications, benefits, and considerations associated with gemstone oiling and crack filling machines.

Burhani Engineering Technology is the largest Producer and Manufacturer of State Of Art High Pressure and Low Temperature Gemstone.

Gemstones, with their exquisite colors and inherent beauty, have captivated human fascination for centuries. To enhance their visual appeal and durability, gemstone professionals employ techniques such as oiling and crack filling. A gemstone oiling and crack filling machine automates and streamlines these processes, ensuring consistent and effective results.

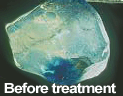

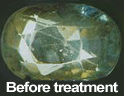

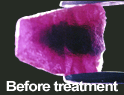

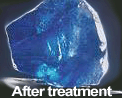

Principles of Gemstone Oiling and Crack Filling :Gemstone oiling involves the application of a colorless or colored oil to the surface of a gemstone. This technique serves multiple purposes, such as enhancing color, masking minor surface imperfections, and improving the overall visual clarity of the stone. Crack filling, on the other hand, involves injecting a filler material into surface-reaching fractures within a gemstone. This process improves the stone's durability and can also enhance its appearance by reducing the visibility of cracks.

Applications of Gemstone Oiling and Crack Filling Machines: 1. Jewelry Manufacturing: Gemstone oiling and crack filling machines are essential tools for jewelry manufacturers. They enable the enhancement of gemstones before they are set into various jewelry pieces, including rings, necklaces, earrings, and bracelets.

2. Gemstone Enhancement: Gemstone dealers and traders use these machines to improve the visual quality of gemstones before presenting them to customers. Enhanced gemstones command higher market value and appeal to a broader range of buyers.

3. Restoration: Antique and vintage jewelry often feature gemstones that have undergone natural wear and tear over time. Gemstone oiling and crack filling machines play a crucial role in restoring the appearance and structural integrity of these precious pieces.

4. Collector's Items: Collectors of gemstones and rare minerals use these machines to enhance the beauty of their specimens, making them more visually captivating for display.

1.Enhanced Visual Appeal: Oiling improves the color and clarity of gemstones, making them more attractive and vibrant. Crack filling reduces the visibility of fractures, enhancing the stone's overall appearance.

2.Increased Durability: Crack filling reinforces gemstones by stabilizing fractures, preventing further propagation of cracks, and enhancing their resistance to wear.

3.Higher Market Value: Enhanced gemstones are often more valuable in the market due to their improved aesthetics and durability.

4.Customer Satisfaction: Jewelry pieces featuring enhanced gemstones are more likely to satisfy customers who appreciate the beauty and longevity of their purchases.

5.Preservation of Heritage: Gemstone oiling and crack filling machines contribute to preserving the aesthetic and historical value of antique and vintage jewelry pieces.

1. Gemstone Compatibility: Not all gemstones are suitable for oiling and crack filling. Some stones may react negatively to the treatment or may not benefit from it.

2. Expertise: Proper training and understanding of gemstone properties are essential to ensure effective treatment without damaging the gem.

3. Quality of Materials: The type and quality of oils and fillers used significantly impacts the results. Using subpar materials can lead to suboptimal enhancements.

4. Ethical Considerations: Transparent disclosure about treatments is essential when selling treated gemstones, ensuring customers make informed purchasing decisions.

5. Maintenance: Regular maintenance of the machine is crucial to ensure consistent performance and prevent cross-contamination between different gemstones.

Oiling and Crack filling machine. The Gemstone crack filling machine is a compact and desktop model that works in any environment.

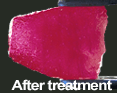

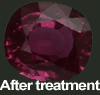

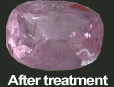

The Burhani Engineering Technology Oiling apparatus is used to induce resins, oils, paraffin, oleoresins and combination of compatible liquid fillers of different viscosity into the surface reaching cracks and fissures on Sapphire, Ruby, Emerald, Tourmaline and many more. The above process helps to produce enhance clarity in the gemstone by hiding their imperfections by increasing their diaphaneity.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Below is the example of TEMPERATURE-PRESSURE CORRELATION VALUES USING PARAFFIN OIL.

75° C <-> 100 bar-1450 psi

80° C <-> 130 bar-1885 psi

85° C <-> 150 bar-2175 psi

90° C <-> 200 bar-2900 psi

95° C <-> 230 bar-3336 psi

120° C <> 260 bar-3771psi

150° C <> 300 bar-4351psi

NOTE: Above Pressure and temperature values shall vary depending on the load, amount and Type of the filler oil used in the Burhani Engineering Technology Crack Filling Chamber, and other variable process parameters.

Emerald oiling and crack filling machine

Heat and pressure oiling and crack filling machine and pressurised resin filling machine Burhani Engineering Technology's position as the largest producer and manufacturer of advanced gemstone treatment equipment is a testament to its commitment to innovation and excellence within the gemstone industry. The 2-in-1 gemstone oiling and crack filling machine, along with the forced epoxy resin machine operating at cold temperatures, offers a comprehensive solution for enhancing the quality and aesthetics of gemstones.

1. Combined Functionality: The 2-in-1 machine's ability to perform both high-pressure and low-temperature treatments in a single device streamlines gemstone enhancement processes, saving time and resources.

2. Versatile Application: The compact and desktop design ensures that these machines can be utilized effectively in various settings, making them suitable for gemstone workshops, laboratories, and other environments.

3. Enhanced Clarity: Through the injection of resins, oils, paraffin, and compatible liquid fillers into surface-reaching cracks and fissures, these machines improve the clarity of gemstones. This process conceals imperfections and enhances diaphaneity, enhancing the gem's visual appeal.

4. Compatibility: The machines are adaptable to various gemstone types, including Sapphire, Ruby, Emerald, Tourmaline, and more. This versatility enables professionals to elevate the quality of a wide range of gemstones.

5. Forced Epoxy Resin at Cold Temperatures: The inclusion of a forced epoxy resin machine operating at cold temperatures offers the capability to stabilize or enhance gemstones with epoxy resin, even at lower temperatures.

6. Advanced Technology: Both machines incorporate advanced technology for precise and

controlled injection of fillers and epoxy resin into gemstones, ensuring consistent and high quality results.

7. Industry Leadership: As the largest producer and manufacturer of such equipment, Burhani

Engineering Technology plays a leading role in advancing gemstone treatment technology.

8. Quality Assurance: These machines contribute to the production of gemstones with

improved clarity and enhanced aesthetics, increasing their desirability and market value.

9. Ethical Practices: Transparency regarding any treatments or enhancements applied to

gemstones is vital for maintaining ethical standards in the gemstone industry.

In summary, Burhani Engineering Technology's gemstone treatment machines are instrumental in elevating the quality and marketability of gemstones. Their innovative features and commitment to ethical practices contribute to the industry's growth and the satisfaction of both professionals and consumers.

The oiling and crack filling process is aimed to reduce the visibility of surface reaching fissures, cracks, crevices and other dislocation features in the gemstone. thus the oil treatment enhances the clarity of gemstone and improves its overall appearance, and thus increases its price.

Rubies, Sapphire, Diamonds, Emerald, Opal, Turquoise, rhodochrosite. many other gemstone porus and non porus can be oiled. Many porous and non-porous gems may be oiled.

All qualities of gemstone can be subjected to the oiling treatment as long as the stone has surface reaching fractures.

Cut and polished gemstones and Rough Stones can be oiled in different ways.

The clarity can be improved from minor to minor to significant change and in some cases there shall be no improvement. Many clarity grades are published by various gem institute. These are subjected to experiments and research.

The oiling process may be permanent if the hardener is used with fillers. The Gemstone should be re-oiled, if the oil is leaked from the Gemstone.

The oiling process can be reversed based on filler material used. If Hardener is combined with filler, then it may be difficult to reverse or remove from the gemstone.

The oiling treatment can be detected by expert Gemologist.

Yes. The Gemstone can get damage due to high heat Jewellery repairs, Steam Treatment, Solvents and other strong solutions. In this case the Gemstone has to be given to the lab for re oiling process.

Colorless Cedar wood oil is regarded as the best available oil in the market today. It is accepted in the international gemstone market. However, cedar wood oil is often mixed with other natural or synthetic substances.

Suitable dye can be mixed with compatible oil filler and be used in the oiling process. Most notable the "Joben" as standard practice of oiling emeralds in India.

Safe pressure for oiling zambian emeralds is about 3500 PSI. Increased in pressure can lead to expansion of frature and break apart.

Oiling and crack filling machines manufactured by Burhani Engineering Technology are safe and simple to operate. However it is the best Low Temperature and high pressure and sophisticated electro mechanical machine in the world.

Innovation, Quality, Prompt Service, On time delivery.

Aimed at delivering value and achieving complete customer satisfaction.

Expertise is in manufacturing high-quality products.

| HOME |

| ABOUT US |

| CAREER |

| CONTACT US |

| DOWNLOADS |

| PRIVACY POLICY |

For all Your Vacuum Chambers,

Vacuum Degassing Chamber, Bubble test Chamber

and Filling machine needs.