A vacuum degassing chamber is a crucial tool in various industries, ranging from manufacturing and metallurgy to research and development. It plays a significant role in ensuring the quality, purity, and performance of materials by removing unwanted gases and impurities. This comprehensive guide will delve into the principles, applications, benefits, and considerations associated with vacuum degassing chambers.

In the world of material processing, purity is paramount. Whether it's in metallurgy, electronics manufacturing, or culinary arts, removing unwanted gases and bubbles from substances can make all the difference in achieving superior results. Vacuum degassing chambers, designed to eliminate entrapped gases in liquids and materials, have become indispensable tools across a diverse range of industries. In this comprehensive guide, we will delve into the world of vacuum degassing chambers, exploring their applications, construction, and the vital role they play in delivering pure, high-quality outcomes in various fields.

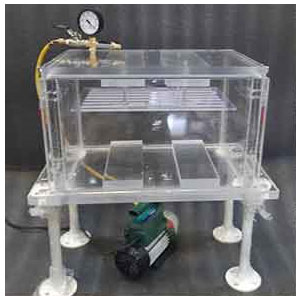

What is a vacuum degassing chamber?Vacuum degassing chamber manufactured by Burhani Engineering Technology is a vacuum system comprising of Vacuum chamber and vacuum pump that pulls 29 inches of mercury is used to remove the air from high viscosity materials like epoxy resin, Liquid silicone rubber, liquid plastic and Polyurethane rubber to make bubble free casting. Burhani Engineering Technology is the only exporter and manufacturer of resin vacuum degasser chamber in India for degassing silicone.

The Essence of Vacuum DegassingBefore we plunge into the intricacies of vacuum degassing chambers, let's first understand the fundamental principle at play. Vacuum degassing is the process of removing dissolved or entrapped gases from a substance by placing it in a controlled vacuum environment. This process is essential in industries where purity, structural integrity, and product performance are paramount.

Introduction to Vacuum Degassing ChambersA vacuum degassing chamber, also known as a degas chamber or vacuum deaeration chamber, is a specialized enclosure designed to create a controlled environment with reduced pressure, enabling the removal of gases dissolved in liquids or trapped within solids. The process involves subjecting materials to a vacuum environment, allowing volatile components to evaporate and escape, resulting in enhanced material quality.

Principles of Vacuum DegassingThe fundamental principle underlying vacuum degassing is Henry's Law, which states that the solubility of a gas in a liquid is directly proportional to the partial pressure of the gas above the liquid. By lowering the pressure in the chamber, the partial pressure of dissolved gases decreases, causing them to be released from the material and collected.

Vacuum degassing chambers find applications across a wide spectrum of industries and processes:

1. Metallurgy: In the realm of metallurgy, vacuum degassing eliminates impurities and gases in molten metal, enhancing material properties and ensuring product quality.

2. Electronics: Electronics manufacturers employ these chambers to remove air bubbles from potting compounds and encapsulants, ensuring the longevity and reliability of electronic components.

3. Food Processing: In culinary arts and food processing, vacuum degassing chambers are used to preserve the freshness of foods, extend shelf life, and enhance flavor profiles.

4. Pharmaceuticals: The pharmaceutical industry relies on vacuum degassing to remove entrapped air and gases from pharmaceutical formulations, ensuring accurate dosing and product stability.

5. Dental: Dental laboratories use these chambers to eliminate bubbles from dental resins, ensuring precise and reliable dental prosthetics.

6. Scientific Research: Researchers across various scientific disciplines use vacuum degassing to prepare samples and reagents with the utmost purity and consistency.

Vacuum degassing chambers are meticulously designed to facilitate the removal of gases from materials. Key components include:

1. Chamber: The vacuum chamber itself is constructed from materials such as stainless steel or acrylic and features an airtight seal to create a controlled environment.

2. Vacuum Pump: A high-performance vacuum pump creates the low-pressure environment necessary for degassing. Different types of pumps, such as rotary vane pumps or oil-free diaphragm pumps, may be used depending on the application.

3. Control System: Advanced control systems allow precise monitoring and adjustment of pressure levels, vacuum duration, and temperature to optimize the degassing process.

4. Lid or Cover: A transparent lid or cover is often included to provide visibility into the chamber during the degassing process.

5. Vacuum Gauge: A vacuum gauge or sensor provides real-time feedback on the pressure within the chamber, ensuring accurate control.

1. Metallurgy and Casting: In the metallurgical industry, vacuum degassing chambers are used to remove dissolved gases from molten metals, ensuring the final product's mechanical properties meet desired standards. This process is essential for producing high-quality steel, aluminum, and other metal alloys.

2. Polymer Industry: Vacuum degassing is employed to eliminate air bubbles and volatile compounds from polymers and resins during their processing. This results in smoother surfaces, improved clarity, and enhanced mechanical properties in the final products.

3. Electronics Manufacturing: Vacuum degassing chambers are used to remove trapped air and moisture from encapsulation materials, ensuring the reliability and longevity of electronic components and assemblies.

4. Food and Beverage: In the food and beverage industry, vacuum degassing is employed to remove unwanted gases such as oxygen from liquid products, thereby extending shelf life and maintaining product quality.

5. Pharmaceuticals: Vacuum degassing chambers are used to remove air bubbles and dissolved gases from pharmaceutical formulations, ensuring accurate dosing and preventing packaging issues.

6. Research and Development: Vacuum degassing is essential in laboratories for various purposes, including purifying reagents, degassing solvents, and preparing samples for analysis.

1. Enhanced Material Quality: Removal of gases and impurities results in improved material properties, such as increased strength, durability, and resistance to corrosion.

2. Reduced Defects: Vacuum degassing reduces the occurrence of defects like porosity, voids, and surface imperfections in materials, leading to higher product reliability.

3. Improved Performance: Materials processed in vacuum degassing chambers exhibit better performance characteristics due to the absence of trapped gases that could hinder functionality.

4. Extended Lifespan: Products free from trapped gases and impurities are less susceptible to degradation over time, resulting in longer service life.

5. Consistent Results: Vacuum degassing ensures consistent material quality, leading to more predictable and repeatable manufacturing processes.

1. Chamber Design: The design of the vacuum chamber should consider factors such as material compatibility, chamber size, and sealing mechanisms to maintain the required vacuum levels.

2. Operating Parameters: Proper control of temperature, pressure, and degassing duration is essential to achieve the desired results without compromising material integrity.

3. Material Compatibility: Different materials may react differently to the vacuum environment, necessitating an understanding of their behavior to prevent undesired reactions or degradation.

4. Maintenance and Cleaning: Regular maintenance and cleaning of the vacuum system are vital to ensure consistent performance and prevent contamination.

5. Safety Precautions: Adequate safety measures must be in place, considering the potential risks associated with working with vacuum equipment, such as implosion hazards and exposure to toxic substances.

| Model No | Capacity Gallon | Capacity Litres | Size Dia x Height (cm) |

|---|---|---|---|

| BHF2020 | 1.7 | 6.3 | 20x20 |

| BHF2520 | 2.6 | 10 | 25x20 |

| BHF3030 | 5.6 | 21 | 30x30 |

| BHF3045 | 8.5 | 32 | 30x45 |

Custom Sizes Manufactured on Demand.

| Model No | Capacity Gallon | Capacity Litres | Size Dia x Height (cm) |

|---|---|---|---|

| BHF4040 | 13.5 | 50 | 40x40 |

| BHF5050 | 27 | 100 | 50x50 |

Custom Sizes Manufactured on Demand.

Vacuum degassing systems employ methods to maximize the surface area under vacuum. A resin degassing chamber is developed and manufactured by Burhani Engineering Technology in the Brand name of Burhani Engineering Technology. We also provide vacuum pump for degassing resin.

The vacuum chamber with pump India is loaded with epoxy resin or silicon rubber or Polyurethane rubber. The Vacuum Pump is started and diy vacuum degassing chamber process is started and it continues for 8 to 10 minutes based on type of resin and quantity.

Vacuum Degassing silicone is a process to remove gases and bubbles from compounds using vacuum chamber and vacuum pump. A diy vacuum degassing chamber is required to assure a bubble free mold when mixing silicone rubbers and mixing resin and slower setting harder resins.

Burhani Engineering Technology Vacuum Chamber customers are using vacuum chamber degassing pot for degassing for over years without a single incident.

Experiments on human and animals have shown that people can survive exposure to vacuum conditions for few minutes. Vacuums are lethal. Under extremely low vacuum air is trapped inside the lungs. It expands and tears the tender gas-exchange tissues

You have to Select appropriate Vacuum Pump for your Acrylic Vacuum Chamber. The highest vacuum that can be expected in an acrylic vacuum chamber is about 750 mm hg. Burhani Engineering Technology also Provides option to go lower with a more powerful degassing chamber and pump

A vacuum is space devoid of air. It is a region with air pressure less that atmospheric pressure. For example, a vacuum cleaner produces enough suction to reduce air pressure by around 20% around its occupied space.

A degassing chamber and pump can cost around $100-$1000 based on material, Sizes and shapes. You can do fun and science experiments to see how things react inside the vacuum. You can also have full viewing since the vacuum chamber price will be totally clear.

Degassing is a process of removal of dissolved gases and bubbles from resins using diy vacuum degassing chamber. Burhani Engineering Technology is best vacuum pump for degassing silicone.

Degassing is an important step after mixing of Resin and Hardener. It is used to eliminate residual pores and Bubbles. These bubbles are created during either mixing or the chemical reaction, or they appear as a result of entrapped air during casting process.

Innovation, Quality, Prompt Service, On time delivery.

Aimed at delivering value and achieving complete customer satisfaction.

Expertise is in manufacturing high-quality products.

| HOME |

| ABOUT US |

| CAREER |

| CONTACT US |

| DOWNLOADS |

| PRIVACY POLICY |

For all Your Vacuum Chambers,

Vacuum Degassing Chamber, Bubble test Chamber

and Filling machine needs.