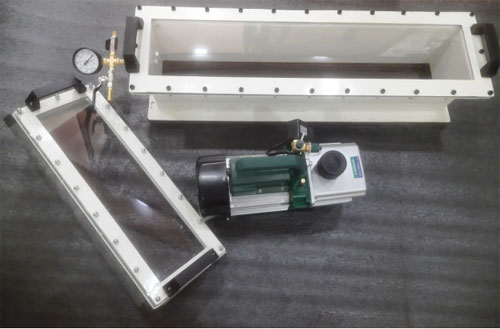

The BHFTECH vacuum box has been designed for the operators according to API 650/653 recommendations. Bubble leak or vacuum box testing is an integral part of tank inspections as required by the American Petroleum Institute (API) and other international standards associations to establish the condition of tank bottom plate welds and shell-to-bottom plate welds

Features

Designed to API 650/653 recommendations

750 mm (29.53 in) weld inspection length, improves inspection times and reduces operator fatigue. Integrated LED lights provide the required light intensity as specified by API and ASME inspection standards. Screen glare and shadows from external light sources are eliminated. Calibrated vacuum relief valve ensures the correct vacuum is generated, too high a vacuum can damage the vacuum box and cause injury to the operator Superior build quality with robust body. Two-stage seal design to improve initial vacuum, especially on large lap welds. Electric vacuum pump or compressor driven

More Efficient: Vacuum Box LEDs

The optional built-in LEDs provide the recommended light intensity along the weld under test by API 650. The internal LEDs eliminate the view window reflection that occurs when external lights are used to brighten the weld inspection area. You can easily turn the LEDs on and off, eliminating the need for you to move standard halogen floodlights as you move around the tank

Better Accuracy: Calibrated Gauge

The V750 Vacuum Box comes with an industrial 50.8 mm (2 in) face pressure gauge rated to 762 mm (30 in) of mercury as required by ASME V Article 10-Bubble Test Vacuum Box Technique. The calibrated gauge offers the necessary confidence in your inspections by ensuring the proper recommended vacuum is generated.

Safer and Quicker: Vacuum

Relief Valve

Using a calibrated vacuum relief valve ensures the recommended vacuum under international standards. The advantage of such a valve is that once the necessary vacuum is achieved, the relief valve opens and maintains this vacuum, preventing it from damaging the vacuum box or injure the operator.

Electric Pump or Compressor

Driven

The BHFTECH Boxes generates a vacuum using an electric pump or an Air Vacuum Generator (AVG), and an external compressor. Inspection

companies tend to use the electric

pump because it is more flexible,

while construction companies tend to

use AVG systems.

High-pressure and Low-pressure Models

Vacuum boxes are rated to 20 in of Hg (10 psi/0.7 bar) recommended for

in-services tanks or 10 in Hg (5 psi/0.4 bar) recommended for new tanks.

BHFTECH models are rated to 20 in of Hg.

Innovation, Quality, Prompt Service, On time delivery.

Aimed at delivering value and achieving complete customer satisfaction.

Expertise is in manufacturing high-quality products.

| HOME |

| ABOUT US |

| CAREER |

| CONTACT US |

| DOWNLOADS |

| PRIVACY POLICY |

For all Your Vacuum Chambers,

Vacuum Degassing Chamber, Bubble test Chamber

and Filling machine needs.