Epoxy resin is a versatile and widely used synthetic polymer material known for its exceptional adhesive, mechanical, and chemical properties. With applications ranging from construction and manufacturing to art and crafts, epoxy resin has become a staple in various industries. This comprehensive guide explores the properties, applications, benefits, and considerations associated with epoxy resin.

Epoxy refers to any of the basic components or cured end products of epoxy resins, as well as a colloquial name for the epoxide functional group. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups.

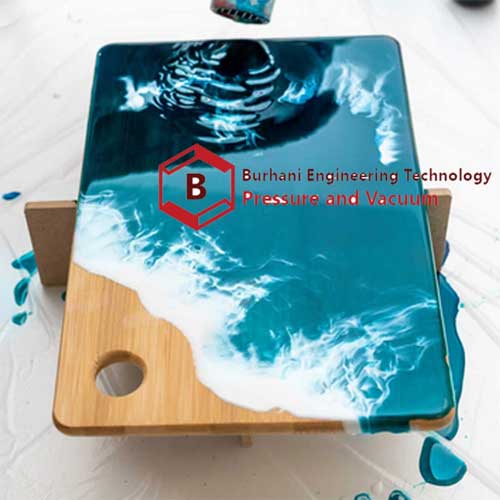

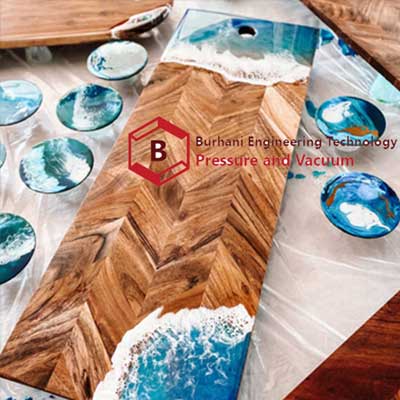

Epoxy resin, mixed with pigment, may be used as a painting medium, by pouring layers on top of each other to form a complete picture. It is also used in jewelry, as a doming resin for decorations and labels, and in decoupage type applications for art, countertops, and tables.

Epoxy resins may be reacted (cross-linked) either with themselves through catalytic homopolymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (usually called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as curing. Reaction of polyepoxides with themselves or with polyfunctional hardeners forms a thermosetting polymer, often with favorable mechanical properties and high thermal and chemical resistance. Epoxy has a wide range of applications, including metal coatings, use in electronics/electrical components/LEDs, high tension electrical insulators, paint brush manufacturing, fiber-reinforced plastic materials, and adhesives for structural and other purposes.

Introduction to Epoxy Resin:

Epoxy resin is a type of thermosetting polymer that forms a hard, durable, and rigid material when cured. It is created by mixing an epoxy resin component with a hardening or curing agent, typically in a specific ratio. The resulting chemical reaction creates a cross-linked structure that offers remarkable strength, resistance, and versatility.

1. Adhesive Strength: Epoxy resin exhibits strong adhesive properties, making it suitable for bonding a wide range of materials, including metals, plastics, ceramics, and wood.

2. Mechanical Strength: Cured epoxy resin is known for its high mechanical strength, which contributes to its durability and ability to withstand stress and impact.

3. Chemical Resistance: Epoxy resin offers excellent resistance to various chemicals, including acids, bases, solvents, and oils, making it ideal for applications in harsh environments.

4. Versatility: Epoxy resin can be modified with additives to achieve specific properties, such as flexibility, flame resistance, and UV stability.

5. Clear and Transparent: When properly processed, epoxy resin can result in a clear and transparent finish, making it popular for art and craft projects.

1. Construction and Infrastructure: Epoxy resin is used in civil engineering for repairing and strengthening concrete structures, as well as for bonding and sealing joints and cracks.

2. Manufacturing and Industrial: It finds application in manufacturing for creating composite materials, encapsulating electronics, and producing molds and prototypes.

3. Aerospace and Automotive: Epoxy resins are used in the aerospace and automotive industries for lightweight composite materials in aircraft, spacecraft, and high-performance vehicles.

4. Electronics: Epoxy resin is used for encapsulating and protecting electronic components, ensuring their longevity and reliability.

5. Art and Crafts: In the art world, epoxy resin is used to create stunning and glossy finishes on paintings, sculptures, jewelry, and other creative projects.

6. Flooring and Coatings: Epoxy resin coatings are applied on floors, walls, and surfaces to provide a protective and attractive finish that is resistant to wear, chemicals, and moisture.

1.Durability: Epoxy resin's strong mechanical properties result in durable products and structures that can withstand various environmental conditions.

2.Adhesion: Its exceptional adhesive capabilities ensure reliable bonding between different materials, contributing to the structural integrity of products.

3.Chemical Resistance: Epoxy resin's resistance to chemicals extends the lifespan of products and surfaces, reducing maintenance and replacement costs.

4.Aesthetic Appeal: In art and crafts, epoxy resin adds a glossy, clear finish that enhances the visual appeal of creations.

5.Customization: Epoxy resin formulations can be tailored to meet specific requirements, allowing for flexibility in applications.

6.Water and Moisture Resistance: Epoxy resin's impermeable nature makes it suitable for applications where exposure to water and moisture is a concern.

1.Mixing Ratios: Accurate mixing of epoxy resin and curing agents is crucial to ensure proper curing and achieve desired properties.

2.Ventilation: Epoxy resin applications should be carried out in well-ventilated areas to prevent exposure to potentially harmful fumes.

3.Safety Gear: Personal protective equipment, including gloves and goggles, should be worn while working with epoxy resin.

4.Curing Time: Curing times can vary based on temperature and humidity, so it's essential to follow manufacturer recommendations.

5.Surface Preparation: Proper surface preparation, including cleaning and sanding, is necessary to ensure strong adhesion.

Innovation, Quality, Prompt Service, On time delivery.

Aimed at delivering value and achieving complete customer satisfaction.

Expertise is in manufacturing high-quality products.

| HOME |

| ABOUT US |

| CAREER |

| CONTACT US |

| DOWNLOADS |

| PRIVACY POLICY |

For all Your Vacuum Chambers,

Vacuum Degassing Chamber, Bubble test Chamber

and Filling machine needs.