In the world of scientific inquiry and technological advancement, vacuum chambers are at the forefront of experimentation and exploration. These sealed, airless environments serve as the canvases upon which scientists and engineers create controlled conditions for a wide array of tests and investigations. Among the myriad materials used in crafting these chambers, stainless steel cube vacuum chambers have garnered immense attention for their unparalleled strength, durability, and adaptability. In this comprehensive guide, we embark on a journey into the realm of stainless-steel cube vacuum chambers, delving into their applications, construction, and the invaluable insights they provide to the scientific community and industries alike.

| Model No | Capacity Gallon | Capacity Litres | Size Inches |

|---|---|---|---|

| BHFGCB080606 | 1.2 | 4.5 | 8x6x6 |

| BHFGCB110808 | 3 | 12 | 11x8x8 |

| BHFGCB121212 | 7 | 27 | 12x12x12 |

| BHFGCB181210 | 10 | 36 | 18x12x10 |

| BHFGCB201413 | 16 | 60 | 20x14x13 |

| BHFGCB181818 | 25 | 95 | 18x18x18 |

| BHFGCB242015 | 31 | 118 | 24x20x15 |

| BHFGCB302016 | 41 | 157 | 30x20x16 |

| BHFGCB322620 | 72 | 272 | 32x26x20 |

Custom Sizes Manufactured on Demand.

Before we immerse ourselves in the world of stainless-steel cube vacuum chambers, it is crucial to comprehend the fundamental principles of vacuum technology. A vacuum chamber is a meticulously sealed container designed to remove air and other gases, thus creating a controlled environment with reduced pressure. The absence of air within these chambers enables researchers to simulate conditions resembling those found in outer space, deep-sea environments, or to carry out experiments devoid of atmospheric interference.

Stainless Steel - The Material of Strength Stainless steel, renowned for its exceptional properties, has emerged as the material of choice for constructing vacuum chamber cubes. Its unique characteristics make it the preferred option for a multitude of applications:

1. Durability: Stainless steel is celebrated for its unparalleled strength and resistance to corrosion. These attributes ensure that vacuum chamber cubes made from stainless steel can endure harsh conditions and maintain structural integrity over time.

2. Airtight Seal: Stainless steel's inherent properties make it ideal for creating airtight seals, which are crucial for maintaining vacuum integrity within the chamber.

3. Thermal Stability: Stainless steel exhibits excellent thermal conductivity and stability, allowing for precise control over temperature conditions within the chamber.

4. Customizability: Stainless steel vacuum chamber cubes can be tailored to various sizes and shapes, accommodating specific experimental requirements and equipment.

Stainless steel cube vacuum chambers find applications across a broad spectrum of scientific disciplines and industries:

1. Materials Science: Researchers employ these chambers to investigate material properties under vacuum conditions, facilitating the development of novel materials with exceptional characteristics.

2. Electronics Testing: Stainless steel chambers provide controlled environments for testing electronic components and circuits, safeguarding them from external atmospheric influences.

3. Space Simulation: Stainless steel cube vacuum chambers are instrumental in simulating space conditions, enabling the testing of spacecraft components and astronaut equipment in real-world scenarios.

4. Biological and Medical Research: These chambers are pivotal in biological and medical research, creating controlled environments for cell culture, tissue engineering, and drug development.

5. Environmental Testing: Stainless steel chambers allow the simulation of extreme environmental conditions, including high altitudes and fluid immersion, for testing aerospace components, diving equipment, and more.

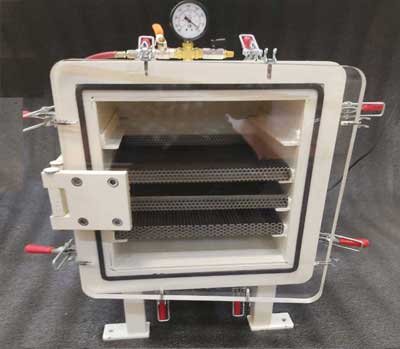

The construction of a stainless-steel cube vacuum chamber demands meticulous planning and precision. Key components include:

1. Stainless Steel Panels: High-quality stainless-steel panels providing structural strength and resilience.

2. Seals and Gaskets: Airtight seals and gaskets are essential to maintain vacuum integrity.

3. Vacuum Pump: A reliable vacuum pump is necessary for evacuating the chamber and regulating pressure levels.

4. Viewports: Transparent windows or viewports for observation and experimentation.

5. Control Valves and Gauges: Instruments for monitoring and adjusting pressure levels within the chamber.

6. Support Structure: A robust support structure ensures stability and safety during experiments.

Prioritizing Safety

Working with vacuum chambers, especially stainless-steel ones, requires strict adherence to safety protocols. Researchers must be well-informed about potential hazards and employ appropriate safety equipment and procedures to mitigate risks effectively.

Innovation, Quality, Prompt Service, On time delivery.

Aimed at delivering value and achieving complete customer satisfaction.

Expertise is in manufacturing high-quality products.

| HOME |

| ABOUT US |

| CAREER |

| CONTACT US |

| DOWNLOADS |

| PRIVACY POLICY |

For all Your Vacuum Chambers,

Vacuum Degassing Chamber, Bubble test Chamber

and Filling machine needs.