In the realm of scientific exploration and experimentation, the use of vacuum chambers plays a pivotal role. These sealed environments devoid of air have enabled researchers to delve into the mysteries of physics, chemistry, and materials science. Among the various materials used to construct these chambers, acrylic vacuum chamber cubes have gained significant popularity for their unique blend of transparency, durability, and versatility. In this comprehensive guide, we will take a deep dive into the world of acrylic vacuum chamber cubes, exploring their applications, construction, and the invaluable insights they provide to scientists and engineers.

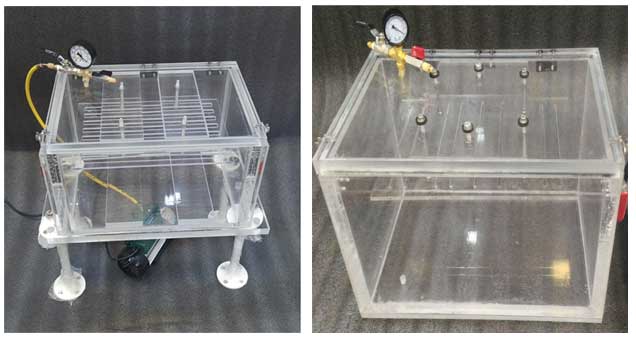

Cube Chambers manufactured by Burhani Engineering Technology are the most versatile of all vacuum chamber configurations.The Clear cube chambers is known for its efficient use of space with high volume testing. Viewports, Shelving, Feedthroughs,lighting and integration with other vacuum accessories. the Standard transparent acrylic vacuum cube chambers include ports for vacuum, vent and gauge. 2 Ball valves and 0-30" vacuum gauge with pneumatic fittings and hose.

Burhani Engineering Technology vacuum chambers feature rugged cast acrylic construction with a cube design. this plastic vacuum chambers can achieve vacuum down to 0.1 Torr. The vacuum chamber rage starts from 6 inches to 40 inches as per customer requirements. Thickness of the chamber ranges from 25 mm to 60 mm thick rugged acrylic.

Burhani Engineering Technology is the largest Manufacturer of clear acrylic cube vacuum chamber in India. These Chambers are used in a variety of application right from research to production. The acrylic plastic vacuum chamber is covered with an acrylic vacuum chamber lid along with vacuum chamber door. This vacuum chamber allows user to perform specified levels of vacuum pressure inside this vacuum chamber. The Entire setup can be controlled manually or automated as per the requirement. 7 inch Touch Screen can be provided on request.

| Model No | Capacity Gallon | Capacity Litres | Size Inches |

|---|---|---|---|

| BHFGCB080606 | 1.2 | 4.5 | 8x6x6 |

| BHFGCB110808 | 3 | 12 | 11x8x8 |

| BHFGCB121212 | 7 | 27 | 12x12x12 |

| BHFGCB181210 | 10 | 36 | 18x12x10 |

| BHFGCB201413 | 16 | 60 | 120x14x13 |

| BHFGCB181818 | 25 | 95 | 18x18x18 |

| BHFGCB242015 | 31 | 118 | 24x20x15 |

| BHFGCB302016 | 41 | 157 | 30x20x16 |

| BHFGCB322620 | 72 | 272 | 32x26x20 |

Custom Sizes Manufactured on Demand.

Fundamentals of Vacuum ChambersBefore we embark on our journey into the world of acrylic vacuum chamber cubes, let's first grasp the fundamentals of vacuum technology. A vacuum chamber is a sealed container from which air and other gases are removed to create a low-pressure environment. This absence of air enables scientists to conduct experiments in conditions that mimic space, deep-sea environments, or simply remove air from specific experiments.

Material for Vacuum Chambers The Superiority of Acrylic

Acrylic, also known as polymethyl methacrylate (PMMA), has become a preferred material for constructing vacuum chambers. Its unique properties make it an excellent choice for various applications:

1.Transparency: Acrylic is renowned for its exceptional optical clarity. Unlike metal or glass, which may obstruct visibility, acrylic allows researchers to observe experiments within the chamber with precision. This transparency is crucial for monitoring reactions, crystallization, and more.

2.Durability: Acrylic vacuum chamber cubes are robust and resistant to impact, making them suitable for a wide range of applications. They are less prone to shattering compared to glass, reducing the risk of accidents in the laboratory.

3.Weight: Acrylic chambers are lighter than their metal counterparts, making them easier to handle and transport. This feature is particularly advantageous when designing portable or field equipment.

4.Versatility: Acrylic can be easily molded into various shapes and sizes, offering flexibility in chamber design. Researchers can customize chambers to accommodate specific experiments and equipment.

Acrylic vacuum chamber cubes find applications across diverse scientific fields:

1. Material Science: Researchers can study the properties of materials under vacuum conditions, facilitating the development of new materials with unique characteristics.

2. Electronics Testing: Acrylic chambers are used to test electronic components and circuits in a controlled environment, free from atmospheric interference.

3. Space Simulation: Acrylic vacuum chambers simulate the conditions of space, enabling the testing of spacecraft components and astronaut equipment.

4. Biology and Medicine: Vacuum chambers are used in biological and medical research to create controlled environments for cell culture, tissue engineering, and drug development.

5. Environmental Testing: Acrylic chambers are employed to simulate extreme environmental conditions such as high altitudes and submersion in fluids for testing products like aerospace components and diving equipment.

The construction of an acrylic vacuum chamber cube requires careful planning and precision. Key components include:

1. Acrylic Panels: High-quality acrylic panels that provide visibility and structural integrity.

2. Seals and Gaskets: Airtight seals and gaskets to maintain vacuum integrity.

3. Vacuum Pump: A reliable vacuum pump to evacuate the chamber and maintain the desired pressure.

4. Viewports: Transparent windows or viewports for observation and experimentation.

5. Valves and Gauges: Control valves and pressure gauges for monitoring and adjusting pressure levels.

6. Support Structure: A sturdy support structure to ensure stability and safety during experiments.

Working with vacuum chambers, even acrylic ones, requires adherence to strict safety protocols. Researchers must be aware of potential hazards, such as implosions, and use proper safety equipment and procedures to mitigate risks.

Acrylic vacuum chamber cubes have revolutionized scientific exploration, providing a window into the invisible realms of vacuum technology. Their transparency, durability, and versatility make them invaluable tools in laboratories and research facilities worldwide. As technology continues to advance, we can only anticipate further innovations in the field of vacuum chamber construction, enabling us to unlock even more of the universe's secrets.

Innovation, Quality, Prompt Service, On time delivery.

Aimed at delivering value and achieving complete customer satisfaction.

Expertise is in manufacturing high-quality products.

| HOME |

| ABOUT US |

| CAREER |

| CONTACT US |

| DOWNLOADS |

| PRIVACY POLICY |

For all Your Vacuum Chambers,

Vacuum Degassing Chamber, Bubble test Chamber

and Filling machine needs.