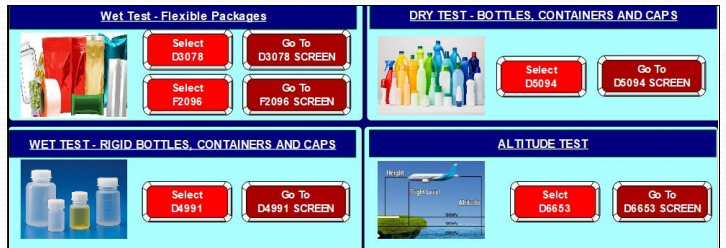

This is a Pressure Leak Test Sterile Barrier System Manufactured by Burhani Engineering Technology for ASTM F2096 Standards

The ASTM F2096 Bubble Test is a destructive, qualitative method for detecting and locating leaks in non-porous, rigid, and flexible packages that contain headspace gaps.

This method is widely used in the pharmaceutical sector and is referenced in the ISO 11607-1 international standards

The Equipment Needed for Test

1.Various Packaging Systems

2. Sterile Barrier System

3. Pressure Generator with Injector Needle

4. Electronic Pressure Regulator

Method A

Steps

1. Stick a rubber Patch on the package and inject needle in the package

2. Submerge the Package Inside the Sterile Barrier Chamber at least 25 mm below water level with the help of dipper plate

3. Use Digital Pressure Control valve to inject compressed air inside the patch stick on package

4. Modify and adjust the pressure air flow inside the package as per requirement

5. Carefully observe for any escaping bubbles indicating leak

The Pressure Leak Test Sterile Barrier System, developed by Burhani Engineering Technology, is a crucial tool for ensuring the integrity of packaging used in various industries, particularly the pharmaceutical sector. This system adheres to ASTM F2096 standards, which are highly regarded in the industry for their effectiveness in detecting leaks in non-porous, rigid, and flexible packages. The ASTM F2096 Bubble Test, the core of this system, is a destructive, qualitative method that identifies and locates leaks in packages that contain headspace gaps, ensuring that products remain sterile and uncontaminated during storage and transportation.

This method is particularly vital in the pharmaceutical sector, where the integrity of sterile barrier systems is paramount. The test is referenced in ISO 11607-1 international standards, underscoring its global recognition and applicability. The equipment required for this test includes various packaging systems, a sterile barrier system, a pressure generator with an injector needle, and an electronic pressure regulator. These components work together to create the conditions necessary for detecting leaks, ensuring that the packaging can withstand the rigors of its intended use.

ASTM F2096, along with ASTM D3078, serves as a standard for testing the integrity of sterile barrier systems. This is particularly important for sealed packages that contain a low volume of inner air, such as sachets and tray packages. These packages are commonly used in the pharmaceutical industry, where even the smallest leak can compromise the sterility of the product. The F2096 standard is used to inspect the airtightness of packaging, helping to pinpoint the location of any failures. This makes it an invaluable tool for quality control and assurance in industries where packaging integrity is critical.

The Bubble Test, a term often used to refer to ASTM F2096, relies on the principle of internal pressurization to detect leaks. By adjusting the pressure and testing time, this method can detect leaks as small as 50 micrometers,making it extremely sensitive and reliable. The test can be performed using either Method A or Method B,depending on the type of packaging material.

Method A is designed for non-porous packaging materials. The test begins by sticking a rubber patch on the package and injecting a needle into it. The package is then submerged in a sterile barrier chamber, at least 25 mm below the water level, using a dipper plate. Compressed air is injected into the patch using a digital pressure control valve, and the pressure and airflow are adjusted as needed. Any escaping bubbles indicate a leak, providing a clear and immediate visual confirmation of the package’s integrity

Method B, on the other hand, is used for porous packaging materials, which are often employed in the pharmaceutical industry to facilitate sterilization without opening the package. In this method, a blocking agent, similar to foamy soap, is applied to the top of the package to make it airtight. This allows the technician to perform the test as prescribed in Method A, ensuring that even porous materials can be effectively tested for leaks.

Overall, the Pressure Leak Test Sterile Barrier System by Burhani Engineering Technology is an essential tool for maintaining the integrity of packaging in the pharmaceutical and other industries. By adhering to ASTM F2096 standards, this system provides a reliable and accurate method for detecting even the smallest leaks, ensuring that products remain safe, sterile, and effective for their intended use.

ASTM f2096-11 bubble test pdf is particularly vital in the pharmaceutical sector, where the integrity of sterile barrier systems is paramount. The test is referenced in ISO 11607-1 international standards, underscoring its global recognition and applicability. The equipment required for this test includes various packaging systems, a sterile barrier system, a pressure generator with an injector needle, and an electronic pressure regulator. These components work together to create the conditions necessary for detecting leaks, ensuring that the packaging can withstand the rigors of its intended use.

ASTM F2096, along with ASTM D3078, serves as a standard for testing the integrity of sterile barrier systems. This is particularly important for sealed packages that contain a low volume of inner air, such as sachets and tray packages. These packages are commonly used in the pharmaceutical industry, where even the smallest leak can compromise the sterility of the product. The F2096 standard is used to inspect the airtightness of packaging, helping to pinpoint the location of any failures. This Bubble leak test Procedure is an invaluable tool for quality control and assurance in industries where packaging integrity is critical.

The Bubble Test, a term often used to refer to ASTM F2096, relies on the principle of internal pressurization to detect leaks found in ASTM F2096 pdf. By adjusting the pressure and testing time, this method can detect leaks as small as 50 micrometers, making it extremely sensitive and reliable. The test can be performed using either Method A or Method B, depending on the type of packaging material.

Method B, on the other hand, is used for porous packaging materials, which are often employed in the pharmaceutical industry to facilitate sterilization without opening the package as per Astm f2096 bubble test pdf. In this method, a blocking agent, similar to foamy soap, is applied to the top of the package to make it airtight. This allows the technician to perform the test as prescribed in Method A, ensuring that even porous materials can be effectively tested for leaks.

Overall, the Pressure Leak Test Sterile Barrier System by Burhani Engineering Technology is an essential tool for maintaining the integrity of packaging in the pharmaceutical and other industries. By adhering to ASTM F2096 standards, this system provides a reliable and accurate method for detecting even the smallest leaks, ensuring that products remain safe, sterile, and effective for their intended use.

Download the Procedure PDF - ASTM F2096 pdf free download

For a detailed guide on Bubble leak test Procedure and how to operate the ASTM F2096 Bubble Leak Test Machine, download our ASTM F2096 latest version PDF. It includes step-by-step instructions, troubleshooting tips, and best practices to ensure you get the most out of your Bubble leak test equipment

Innovation, Quality, Prompt Service, On time delivery.

Aimed at delivering value and achieving complete customer satisfaction.

Expertise is in manufacturing high-quality products.

| HOME |

| ABOUT US |

| CAREER |

| CONTACT US |

| DOWNLOADS |

| PRIVACY POLICY |

For all Your Vacuum Chambers,

Vacuum Degassing Chamber, Bubble test Chamber

and Filling machine needs.